Division of Crop Production

ICAR – Indian Institute of Pulses Research

Introduction

The Division of Crop Production encompasses key disciplines of agronomy, soil science, farm machinery, and post-harvest technology, supported by a team of ten dedicated scientists (including Head of Division). The division spearheads cutting-edge research aimed at transforming pulse production towards higher productivity, sustainability, and climate resilience. Its research portfolio spans from system-based agronomy, integrated nutrient-water-weed management, and resource-efficient production technologies to frontier domains such as organic and natural farming, nano-enabled inputs, agronomic bio-fortification, precision mechanization, and post-harvest innovation. Through holistic and adaptive approaches, the division strives to redefine the paradigms of sustainable pulses production for enhanced livelihood and environmental security.

Thrust areas:

- Long term effect of pulses in cropping systems and sustainable intensification.

- Input use efficiency (water, nutrients, agro-chemicals and energy).

- Resource conservation technologies and weed management.

- Regenerative and Nature based agronomy in pulse based cropping system.

- Post-harvest management and value addition.

- Precision farm mechanization (AI, IoT based equipment, precision machine).

- New Generation Agronomy (nano-fertilizers, bio-stimulants, agronomic biofortification, and climate resilient agriculture).

Theme-wise brief research achievements:

1. Diversification of Maize-wheat system with Pulses: Long term Impacts

- Pulse inclusive maize-based rotation increased active and passive C-pools in soil. Pigeonpea (P)-wheat (W) and maize (M)-W-Mungbean (Mb) rotation contains maximum amount of available nutrient and soil C- pools in soil over the conventional M-W rotation. The effect of pulse inclusion was prominent on soil C and P- bioavailability.

- Pulse inclusive rotation improves soil aggregation and the effect was conspicuous in the P-W and M-W-Mb rotation. Along with this pulse inclusion improves mean weight diameter, bulk density and water holding capacity.

- All the Pulse inclusive rotation favoured C-sequestration, soil microbial biomass C (SMBC), soil enzymatic activity. Most prominent change in pulse-based systems noticed in alkaline phosphatase and dehydrogenase activity.

- Inclusion of summer mung bean in the M-W system improves base crop productivity as well as system productivity. Pulses are found equally responsive in the integrated and recommended dose of fertiliser conditions.

2. Diversification of Rice-wheat system with Pulses: Long term Impacts

- Rice inclusive pulse-based rotations increased active and passive C-pools in soil. Rice (R)-W-Mb had the highest positive impact on soil nutrient availability (N, P, K, S) and C-availability. The effect of pulse inclusion is also prominent in P-availability.

- Pulse inclusive rotation improved soil aggregation and the highest change was observed in the R-W-Mb rotation under the integrated nutrient management system.

- Pulse inclusive rotation positively impacted C-sequestration in the macro-fractions.

- Significant impact was observed in SMBC and soil enzymatic activity, with the most prominent effect in the R-W-Mb system, followed by the R-chickpea (C) system.

- Inclusion of summer mungbean improves base crop productivity (rice) as well as system productivity. In rice-based systems, pulses become more responsive under INM practices.

3. Conservation agriculture for sustainable intensification

- CA in pulse based systems: CT puddled transplanted rice (CTDSR) –ZT in the post rainy season (CT-ZT) and rice-chickpea/wheat-mungbean increased rice yield by 17% and wheat by 13% than conventionally tilled rice-wheat. Pulses intensive system had superior sustainable yield index of rice by 8.1%, wheat 7.7% and chickpea by 11% than rice-wheat.

- Summer mungbean under CA in rice-wheat system: The grain yield of mungbean increased by 24.4% under zero tillage (ZT) over conventional tillage (CT). Virat had highest grain yield (1478 Kg/ha) among all the mungbean varieties. Residue retention improved mungbean yield by 9.3% over its removal. System productivity in terms of mungbean equivalent yield was higher in ZT (4232 Kg/ha), residue retention (4392 Kg/ha) and Virat (4338 Kg/ha) over CT.

- CA in rice-chickpea system: ZT puddled transplanted rice (ZTDSR) –ZT chickpea (ZTC) + residue (~CA) had higher yield (crops and system) than CT. Apart from higher net return in zero tilled system, additional benefit of Rs. 35000-40000 gained under ZTDSR-ZT system than CT.

- CA for improved soil aggregation, C-sequestration and microbial activity: Significantly higher soil aggregation (24%) was recorded in ZTDSR over CT. Rice-chickpea-mungbean (R-W-Mb) and ZT rice (ZTDSR) had 22% higher C-sequestration over CT and rice-wheat system. Soil microbial biomass carbon (SMBC) increased by ~70% in ZTDSR and pulse inclusive system over intensively cultivated CT plots.

4. Precision irrigation in pulse crops

- Chickpea: Sprinkler irrigation applied in the branch and pod development stage gave higher grain yield (16.1%), biomass (9%), harvest index (5.7%), net return (22.4%), BCR (22.8%) and productivity per day (16.4%) in comparison to sprinkler irrigation in the branching phase only.

- Pigeonpea (long duration): Two distinctive stages coinciding with peak branching stage (90-100 days) and pod development (200-210 days) have been identified as the critical stage for lifesaving irrigation. Drip irrigation with IW: CPE ratio 0.4 found suitable for irrigating the crop.

- Lentil: Higher grain yield (12%), biomass (9.7%), harvest index (5.7%), net return (11.2%), and productivity per day (12%) were found in sprinkler irrigation applied only at branching over that in flood irrigation system. Water use efficiency (14.3%) and water productivity (12.5%) recorded with sprinkler at branching over the flood.

- Urdbean and mungbean: Frequent shallow irrigation with micro sprinklers at different crop stages gave almost at par yield over normal flood irrigation. Sprinkler irrigation had 21.5% less water use with 83.5% higher WUE, WP (83%), net return (53.5%) and BCR (19.6 % and 0.61) over flood irrigation.

- Fieldpea: Higher WP (1.53 times), crop productivity (1.5 q/ha) and increased biomass along with higher pods per plant & grain weight/plant were recorded in sprinkler irrigation at branching and pod development stage.

- Hydrogel: There is no scaling in chickpea productivity or profit following application of hydrogen (even at higher dose of 5 Kg/ha).

- Salicylic acid (SA) @ 100 ppm showed advantage in respect of chickpea grain yield (22.4%), WUE (20.1%), WP (15.3%) and net return (31.2%) over water spray. Urea (2%) or NPK (0.5%) were also equally effective with that of SA 100 ppm in chickpea.

5. Agro-technologies for rainfed rice-fallow of India

I. Rice + urdbean/mungbean/lathyrus/lentil relay cropping

- Broadcasting pulse seeds 7 to 10 days before rice harvest

- Use of 25% higher seed rate of pulses in relay cropping

- Seed priming (soaking the seeds for 4 to 6 hours) in water and micronutrient solutions

- Seed treatment with fungicide, rhizobium, PSB and PGPRs

- Maintenance of 20 to 30 cm rice stubble on the ground to conserve soil moisture

- Foliar spray with 2% Urea/DAP, first at 50% flowering and again after 10 days

- Rice ratoon and weed control: Quizalophos ethyl @ 50 to 100 g a.i./ha

- Following IPM modules for disease and pest management

- Use of farm ponds for water harvesting and lifesaving irrigation with sprinklers

- Rice cultivation through transplanting under unpuddled conditions and DSR

II. Rice – lentil/chickpea/pea sequential cropping

- Sowing of pulses under zero tillage just after harvest of rice

- Use of medium or short duration, high yielding and multiple disease resistance pulses varieties

- Remaining practices as mentioned under relay cropping

6. Organic farming in pulses

- Significantly higher yield in wheat (5.73 t/ha) can be realized through organic practice only. Potential productivity in wheat can also be achieved by foliar supply of organic forms of Zinc (Biozinc), Phosphorus (Biophos) and vermiwash. Higher economic gain in terms of gross returns and B:C ratio (1.83) was recorded under organic cultivation compared to conventional in green manure–wheat–mungbean cropping system.

-

Pulses-based Natural Farming System

The natural farming system evaluated in pulse-based cropping/intercropping systems showed that higher system productivity was recorded under organic farming with the urdbean + bajra – chickpea + mustard cropping system, followed by recommended farming practices. The maximum yield of chickpea (1.68 t/ha) was recorded under chickpea sole, which was significantly higher than chickpea + mustard and chickpea + barley systems. - Higher system productivity was recorded under organic farming (5.01 t/ha) with the urdbean + bajra – chickpea + mustard cropping system, followed by recommended farming practices over others. The order of system productivity was: Organic farming > Recommended practice > Natural farming > Control.

7. Weed management in pulses

I. Chemical weed management

- Kharif pulses (mungbean, urdbean and pigeonpea) Pendimethalin 1.0 kg a.i./ha (PRE) and Imezathapyr 100 g a.i./ha (POST) at 20–25 DAS

- Rabi pulses (chickpea, lentil and pea) Pendimethalin 1.0 kg a.i./ha (PRE), Quizalofop-ethyl 100 g a.i./ha (POST) at 20–25 DAS

- Spring/summer system (mungbean and urdbean) Imezathapyr 80 g a.i./ha (POST) at 20–25 DAS (after first irrigation)

- New post emergence herbicide Clodinafop-propagyl + sodium aciflurofen 187.5 ml a.i./ha at 15–20 DAS in mungbean and Topramezone 20.6 ml a.i./ha at 14–21 DAS in chickpea

II. Rice-chickpea system

- Pendimethalin 1.0 kg a.i. /ha (PRE) and Bispyribac-Na 20 g a.i./ha at 20 DAS in rice

- Oxyflurofen 150 g a.i./ ha (PRE)- propaquizafop 100 g a.i./ ha (POST) at 25 DAS in chickpea.

Weed management in rice-chickpea system

III. Ratoon management in rice fallow

- Quizalophop ethyl 100 g a.i./ha (POST) at 20-25 DAS in pulses in rice-pulse based cropping system.

- Glyphosate 1.0 kg a.i./ha as pre-plant application in pulses for rice fallow condition.

8. Soil P management and dynamics under pulse-based systems

- Plant growth parameters like Leaf chlorophyll content, nitrate reductase activity and plant biomass and others growth parameters influenced positively by 20-30% under poultry manure (1.0 t/ha) incorporation as compared to control (-P) plots.

- System productivity is higher i.e 10% (pigeonpea-wheat) and 9% (pearl millet-chickpea) with crop residue (50%) + PSB application over control.

Effect of integrated P-management on productivity of cropping system

- P solubilisation study revealed that cumulative P mineralization was maximum with poultry manure @ 1.0 t/ha, recording 34 percent higher values over control. Among residues, pearl millet released maximum P compared to others.

- Across crops, overall soluble P fraction increased in poultry manure (PM) added plots by 30 to 35 percent compared to control and was significantly higher than RDF. Adsorption study showed that manure addition reduced adsorption maxima (Xm) due to: (1) saturation of P adsorption sites, and (2) organic carbon covering on oxides and carbonates.

9. Zinc accounting and enrichment in pulses

- Foliar spray at 0.5% ZnSO4 (sprayed at the pre-flowering and pod formation stage) had reported to have higher seed zinc content of 65 to 75 ppm which was 20-25% higher than control.

- Genotypes like JG 16, GNG 2171, IPC 10 62 and GNG 469, Vijay, GNG 2171 are soil and foliar applied zinc responsive genotypes, respectively. Whereas, Vijay, GNG 469, JAKI 9218 can utilise soil and foliar Zn efficiently.

10. Utilization of pulses milling byproduct for edible use

- Pulses are consumed after dehusking and splitting, in form of dal. The byproduct obtained during the milling process is rich in bioactive compounds, viz., protein, fibre, phenol, anticarcinogenic compounds and antioxidants. These milling byproducts can be used for making many edible food products.

- Husk component therapeutic values are mainly antioxidant activity, polyphenolic compounds and fibers

- Powder component (Pulse Protein) can be used for making pulse-based recipes including bakery products.

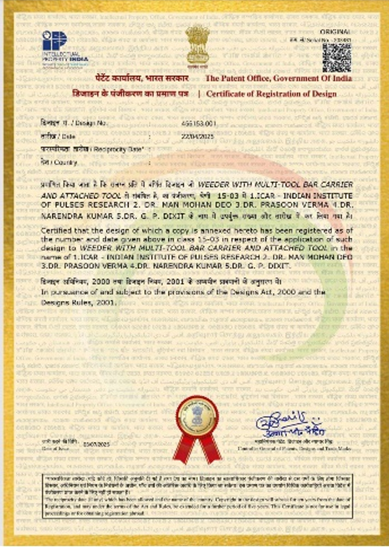

Patent:

Technology certified by ICAR

| Technology | Certificate | Technology | Certificate |

|---|---|---|---|

|

Deciphering the mechanisms of carbon sequestration and stabilization in soil aggregates with diversified cereal-legume rotations in IGP region (Fluvisol)

Study on carbon movement, stabilization in soil aggregates and management practices for enhanced carbon sequestration in Indo-Gangetic Plains (Fluvisol). |

|

IIPR Herbicide Applicator

Training and certification on correct herbicide application techniques (IIPR course). |

|

|

Clodinafop-propargyl + Na-acifluorfen

A selective post-emergence herbicide identified for efficient weed control in mungbean. |

|

IIPR Manual Weeder

Guidelines and certification for manual weeder operations and training. |

|

|

Topramezone

A selective post-emergence herbicide identified for efficient weed control in chickpea. |

|

Protocols for milling of pulses in IIPR mini dal mill

Standard operating procedures and protocols for mini dal mill operations (IIPR). |

|

Pre- and post-harvest mechanization and value addition

|

IIPR Dal Chakki

|

Improved IIPR Mini Dal Mill

|

IIPR Multi-purpose Grinder

|

|

IIPR Vertical Thresher

|

IIPR Pigeonpea Stripper

|

IIPR Suction Winnower

|

|

IIPR Horizontal Hand Chakki

|

IIPR Vertical Hand Chakki

|

IIPR Manual Weeder

|

Technologies available for commercialization

- IIPR Mini Dal Mill

- IIPR Dal Chakki

- IIPR Manual Weeder

- IIPR Herbicide Applicator

- Pulse Threshing and Allied Machines

- IIPR Vertical Thresher

- IIPR Pigeonpea Stripper

- IIPR Suction Winnower

- Multipurpose grinder

- Hand operated vertical dal chakki

- Hand operated horizontal dal chakki

- Utilization of pulse milling byproducts for edible use – Protein & Fiber Rich Biscuits

- Utilization of pulse milling byproducts for edible use – Dal Analogue

- Utilization of pulse milling byproducts for edible use – Pizza Base

- Utilization of pulse milling byproducts for edible use – Bun

- Utilization of pulse milling byproducts for edible use – Cakes and Muffins

- Utilization of pulse milling byproducts for edible use – Noodles

- Utilization of pulse milling byproducts for edible use – Instant Pulse Soup

- Utilization of pulse milling byproducts for edible use – Instant Dal

- Utilization of pulse milling byproducts for edible use – Flour (Atta) Mix

- Utilization of pulse milling byproducts for edible use – Sattu

- Utilization of pulse milling byproducts for edible use – Nachos

- Protocols for milling of pulses in IIPR Mini Dal Mill

On-going research projects:

A. Institute funded

| S.No. | Title of the project | Principal Investigator |

|---|---|---|

|

Programme 1. Innovative strategies for climate-resilient and resource-efficient technologies for sustainable pulses production Coordinator/PI: Dr. Narendra Kumar |

||

| 1 | Carbon-footprint and microbiome community structure in long-term pulses inclusive cropping systems | Dr. Narendra Kumar |

| 2 | Enhancing nutrient use efficiency, crop productivity, and soil health in pulse-based production system through smart nutrient management including nano-fertilizers | Dr. Mohmmad Hashim |

| 3 | Sustainable nutrient management in pulse-based cropping system through microbial interventions under diverse tillage regimes | Dr. Adarsh Kumar |

| 4 | Enhancing sustainability of maize-chickpea cropping system through precision irrigation strategies | Dr. Adarsh Kumar |

| 5 | Improving productivity of pigeonpea-wheat system through efficient resource recycling and smart agriculture technologies | Dr. K.K. Hazra |

| 6 | Innovations in conservation agriculture in pulse-based systems for resilient future farming | Dr. C.P. Nath |

| 7 | Development of climate-smart weed management practices for sustaining pulse-based production systems | Dr. C.P. Nath |

| 8 | Developing advanced yield predictive models of pulse crop for future climate scenarios with decision support framework | Dr. K.K. Hazra |

| 9 | Implementing organic and natural farming in pulse-based production systems for agro-ecological sustainability and improved climate resilience | Dr. Mohmmad Hashim |

|

Programme 2: Advanced engineering interventions for mechanized pulse production and post-harvest management Coordinator/PI: Dr. Prasoon Verma |

||

| 1 | Development of database for physical and engineering parameters contributing to milling recovery and value-added products for major pulses | Dr. Prasoon Verma |

| 2 | Design and development of farm machineries for drudgery reduction and efficient field operation | Dr. Man Mohan Deo |

| 3 | New generation tools and techniques for farm mechanization in pulses | >Dr. Man Mohan Deo |

| 4 | Utilization of pigeonpea crop residue for soil health, energy pellets and fuel wood | >Dr. Prasoon Verma |

B. Externally funded

| S. No. | Title of project | Funding agency | Principal investigator |

|---|---|---|---|

| 1. | Carbon foot-print and microbiome community structure in diversified cropping systems under conservation and conventional agriculture (2023-26) | DST-SERB | Dr. Narendra Kumar |

| 2. | Identification of chickpea genotype for higher phosphorus use efficiency (2023-26) | DST-SERB | Dr. C.P. Nath |

| 3. | Study on determining storage losses of pulses stored in warehouses and to recommend norms for loss/gain during long-term storage (2023-26) | Department of Consumer Affairs (DoCA) | Dr. Prasoon Verma |

| 4. | Crop residue management in rice-wheat-mungbean system for achieving sustainable development goals (2023-26) | UPCST | Dr. C.P. Nath |

| 5. | Conservation agriculture-led management of drought and heat stress of pulse-based cropping system in Bundelkhand region of Uttar Pradesh through participatory approach (2024-27) | UPCAR | Dr. C.P. Nath |

| 6. | Agri-Drone Project (2023-26) | DAC | Dr. Narendra Kumar |

| 7. | Enhancing Lentil Productivity with Osmolytes/Bio-Regulators Induced Tolerance to Terminal Deficit Water and High Temperature Conditions (2024-27) | UPCST | Dr. K.K. Hazra |

| 8. | Impact of Natural Farming on Soil Health, Nutrient Cycling on Sustainability of Pulses-based Cropping System in Indo-Gangetic Plain Region (2025-27) | MNNF (Department of Agriculture & Farmers Welfare) | Dr. Mohd. Hashim |

Facilities Available in The Division

|

Hot Air Oven

|

Flame Photometer

|

Micro Wave Digestion Unit

|

|

Atomic Absorption Spectrophotometer

|

Electrical Conductivity and pH meter

|

Elga Ultra Water Purification System

|

|

Spectrophotometer

|

Nitrogen Analyzer

|

Hot Water Bath

|

|

BOD Incubator

|

Texture Analyzer

|

Net House Facility

|

|

Overall view of soil chemistry lab

|

Pulse Processing Complex

|

Scientists and their area of specialization